Skuteczność i Wybór - Najlepszy Krem Do Twarzy na Dzień dla Twojej Skóry

Physics Aptitude Test (PAT)

Everyone who applies to study physics or physics and philosophy at Oxford, without exception, must take the Physics Aptitude Test (PAT), a two-hour test that evaluates a student’s ability in both physics and maths.

The date of the next PAT will be 28 October 2024. Registration information for the PAT can be found here.

From 2024, the PAT will be online and delivered via Pearson VUE’s established network of test centres. It remains the case that in 2024 there will be no charge for candidates to register for Oxford's own admissions tests.

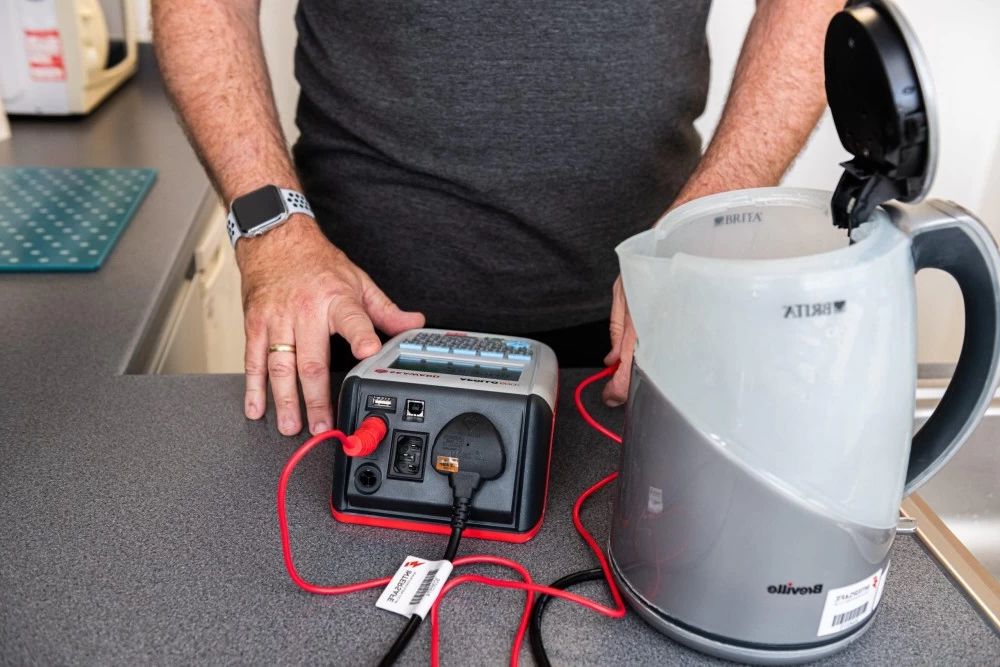

What needs to be PAT tested?

PAT testing should be carried out on any electrical appliance that can cause harm, either by electrical shock or fire. This includes portable appliances, such as kettles, toasters, hairdryers, and larger appliances, like fridges, ovens, and washing machines.

Other portable electrical appliances requiring testing include power tools, extension leads, and computer equipment.

It's important to note that not all appliances need to be tested at the same frequency. The testing interval will depend on various factors, such as the type of appliance, its usage, and the environment it's used in.

Conclusion.

In conclusion, PAT testing is an essential process for ensuring the safety of electrical appliances in both residential and commercial settings. Through a combination of visual inspections and electrical testing, potential hazards can be identified and addressed before they cause accidents.

PAT testing is not a legal requirement but is recommended by regulatory bodies such as the Health and Safety Executive (HSE) and the Institute of Electrical Engineers (IEE) to comply with legal requirements for employers and landlords to maintain their electrical equipment and appliances in a safe condition.

It's important to carry out a risk assessment to determine the frequency of testing and to keep a record of all tests carried out. PAT testing labels and certificates help track which appliances have been tested, when they are due for re-testing, and who carried out the testing.

While PAT testing can be carried out by anyone who has the necessary knowledge and skills, it's recommended to hire a professional PAT tester to ensure accurate and compliant testing and certification. By prioritizing PAT testing, individuals and businesses can ensure the safety of themselves and others while complying with legal requirements.

The PAT Appliance Classes – Defined

Class 1

These electrical appliances only have simple insulation and instead, rely on earth for protection. Such devices are the most common.

Class 2

These electronic devices are outfitted with supplementary insulation and therefore have no reliance on earth for protection. Such devices will be identifiable with a double insulated marking (a square within a square): usually found on the manufacturer’s plate.

Class 3

Low voltage electricals: they are the safest of the classes. They do not require a PAT test, however, the charging lead and cables may do. Class 3 devices will often carry a symbol that contains three vertical stripes within a diamond.

What is a PAT Test?

Defined as Portable Appliance Testing (PAT), it is a routine inspection or examination of various types of electrical equipment and appliances to determine if they are safe to use: this is to prevent accidents or harm to humans, animals and property in the workplace.

Though many defects of electrical equipment can be visually determined, PAT testing also involves a cable inspection using specialist PAT testing tools. The full PAT test is simple to break down:

- Visual inspection of the electrical appliance

- Cable inspection – using PAT testing equipment

The cable inspection portion of a PAT test will include checks and confirmations of the earthing continuity, lead polarity and the integrity of the insulation resistance.

The definition of PAT can be somewhat misleading, however, particularly the word “portable”: appliances that fall under PAT can be any appliance that has a plug attached to connect it to a wall outlet.

There are three distinct classes of electrical appliances: Class 1, Class 2 and Class 3. Class 1 devices are the most dangerous and require a full PAT test.

U nas zapłacisz kartą

U nas zapłacisz kartą